BLMT mechanical cable lugs with shear bolts Accept customization

We stick to our company spirit of "Quality, Effectiveness, Innovation and Integrity". We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for Discount Price Termination Connector Shearbolt/ Mechanical Cable Lug, If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

Discount Price China Torsion Lug and Bolt Cable Lug, Due to the stability of our goods, timely supply and our sincere service, we have been able to sell our products not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We are going to do our best to serve your company, and establish a successful and friendly cooperation with you.

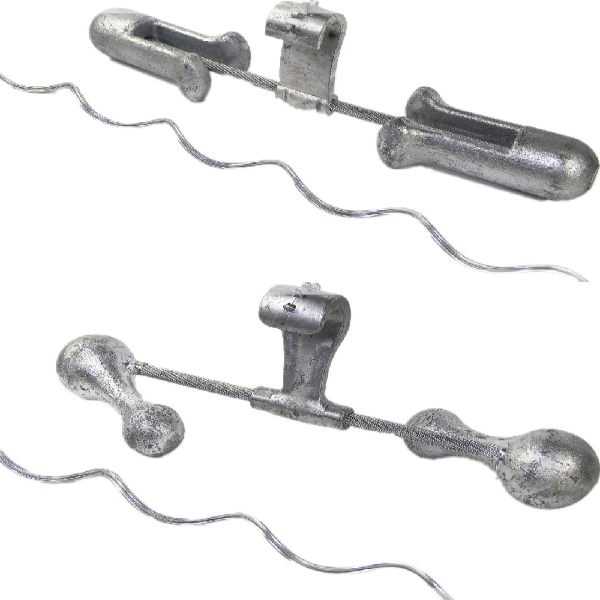

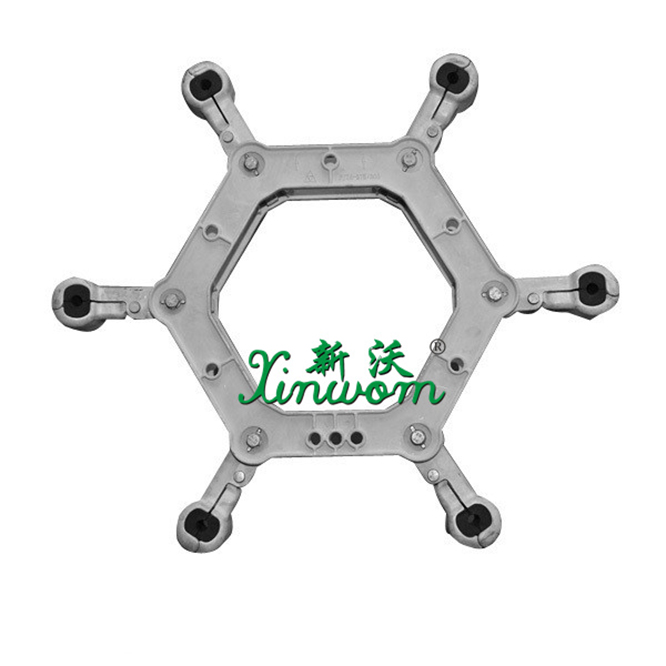

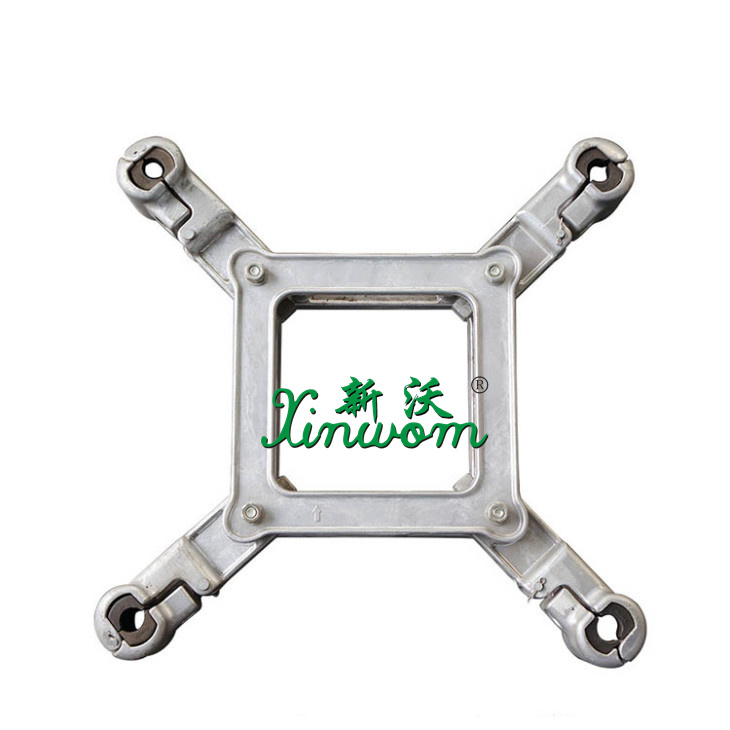

1. Product overview Product name:Torque Terminals(BLMT series) Model representation method BLMT-□□/□□-□□ BLMT-diameter of mounting recess/suitable conductor range-product model 2. Application Torsion terminals are connectors used for connecting wires to equipment, mainly used for connecting insulated wires, aluminum wires, aluminum alloy wires, steel-core aluminum wires and copper wires at non-bearing positions. 3. Scope of application Applicable leading line:25-240㎜². 4.Technical parameters ①The body of the product is made of high strength tin-plated aluminum alloy ②The inner surface of the wire hole has a threaded groove design ③Torque bolts adopt double shear head design to ensure that the bolt can not be removed after cutting head, the bottom of the bolt has a contact ring, better guarantee the electrical properties of the product. ④With a special pad, take it out or put it in, and adjust the product's range of applicable wires, three products will ensure that all wires from 25㎜²-240㎜² are applicable 5. Installation steps ①Check the type and diameter of the wire and select the appropriate type of torque terminal to determine whether the pad wire is used. Catalog No. Suitable Conductor mm² Diameter(mm) Position and diameter of mounting hole Blot No. Specification of bolt head AF(mm) Stripping Length (mm) L1 L2 D1 D2 BLMT-6/50-13 6-50 50 20 18 10 13 1 13 25 BLMT-25/95-13 25-95 60 30 24 12.8 13 1 13 34 BLMT-25/95-17 25-95 60 30 24 12.8 17 1 13 34 BLMT-35/150-13 35-150 86 36 28 15.8 13 1 17 41 BLMT-35/150-17 35-150 86 36 28 15.8 17 1 17 41 BLMT-95/240-13 95-240 112 61 33 20.2 13 2 19 70 BLMT-95/240-17 95-240 112 60 33 20 17 2 19 70 BLMT-95/240-21 95-240 112 60 33 20 21 2 19 70 BLMT-120/300-13 120-300 115 65 37 24 13 2 22 70 BLMT-120/300-17 120-300 120 65 37 24 17 2 22 70 BLMT-185/400-13 185-400 137 80 42 25.5 13 3 22 90 BLMT-185/400-17 185-400 137 80 42 25.5 17 3 22 90 BLMT-185/400-21 185-400 137 80 42 25.5 21 3 22 90 BLMT-500/630-13 500-630 150 95 50 33 13 3 27 100 BLMT-500/630-17 500-630 150 95 50 33 17 3 27 100 BLMT-500/630-21 500-630 150 95 50 33 21 3 27 100 BLMT-630/800-13(customized) 630-800 180 105 61 40.5 13 4 19 118 BLMT-630/800-17(customized) 630-800 180 105 61 40.5 17 4 19 118 BLMT-800/1000-17 800-1000 153 86 60 40.5 17 4 13 94 BLMT-1500-17(customized) 1500 200 120 65 46 17 4 19 130 ②.To measure the length of the end conductor inner hole, to determine the length of wire peel (length of the conductor inner hole L-wire peel length L2≤2 mm). ③Insert the wire into the terminal and install the mechanical bolt. ④Apply force with socket wrench until torque bolt head is cut. ⑤Use suitable bolts to secure the Mechanical cable lugs to the equipment. 6.Features and Advantages ▪ Wide range of applications ▪ Compact design ▪ Can be used with almost any type of conductor and material ▪ Constant torque shear head nuts ensure good electrical contact performance ▪ Easy installation using standard socket wrenches ▪ Pre-engineered for perfect installation on medium voltage cables up to 42kV ▪ Good overcurrent and short-time current shock resistance The lugbody is made of a high tension tinned aluminum alloy. Terminals are suitable for outdoor and indoor applications and are available in different palm aperture sizes. Mechanical bolt type1 Made of special aluminum alloy, these contact bolts are hexagon head double shear head bolts. The bolts are treated with a high quality lubricant and are equipped with a special contact ring. These contact bolts cannot be removed once the bolt head is cut. Mechanical bolt type2 The screw tooth of torsion bolt is designed with foursections, so that the fracture of installation tightening wirewill sink into the surface of the connecting pipe,Bolt with inner hexagon design,Remove the bolt during maintenance,The body can be used over and over again,Reduce construction cost Accessories Special accessories, in or out can adjust the applicable conductor range. These plug-ins have longitudinal stripes and a positioning slot. The installation ▪ Does not need special tools to install, only a socket wrench can be installed; ▪ The same reduction length for each type, including the provision of inserts; ▪ Design of graded torque scissors head nuts to ensure reliable and firm contact; ▪ Each joint or cable lug has its own installation instruction; ▪ We recommend using a support tool (see attachment) to prevent conductor bending. ▪Hexagonal socket with correct A/F dimensions ▪Ratchet wrench Or electric impact wrench ▪It is strongly recommended to use a clamp to provide support for shearing bolts during shearing and to prevent conductor bending